Who am I?

I'm an electrical engineer with a focus on test engineering, and an interest in systems that

will be operating right up to their limits. To that end, I've spent much of my formative years

working on racecars and working for companies on the bleeding-edge.

Where did I go to school?

RIT Formula SAE Racing Team

Aug 2013 - Jul 2018

Most of my spare time during college was spent on the RIT Formula SAE Racing team, tackling

various roles and projects over 5 years.

Elected to Project Manager for 2017-'18 season, tasked with managing team's finances,

schedule, and relationship with RIT faculty and staff. Successfully led team to design

finals with combustion car in all three of its competitions and 2nd Place Overall with

electric car.

- Competition Highlights

- Formula SAE Michigan 2018 - 16th Overall of 120 Registered Teams

- Design: 6th

- Endurance: 17th

- Formula North Combustion 2018 - 17th of 35 Registered Teams

- Formula North Electric 2018 - 2nd of 13 Registered Teams

- Efficiency: 1st

- Endurance: 2nd

- Formula Student UK 2018 - 28th of 81 Registered Teams

- Design: 6th

- Skidpad: 3rd

- Autocross: 9th

Developed embedded systems boards and firmware for use on racecar for purposes of

data acquisition and driver display. Developed deep relationship with combustion

powertrain group to facilitate facilitate deeper understanding of ECU's behavior and

capabilities beyond engine control. This dashboard competed on the 2017 and 2018 cars.

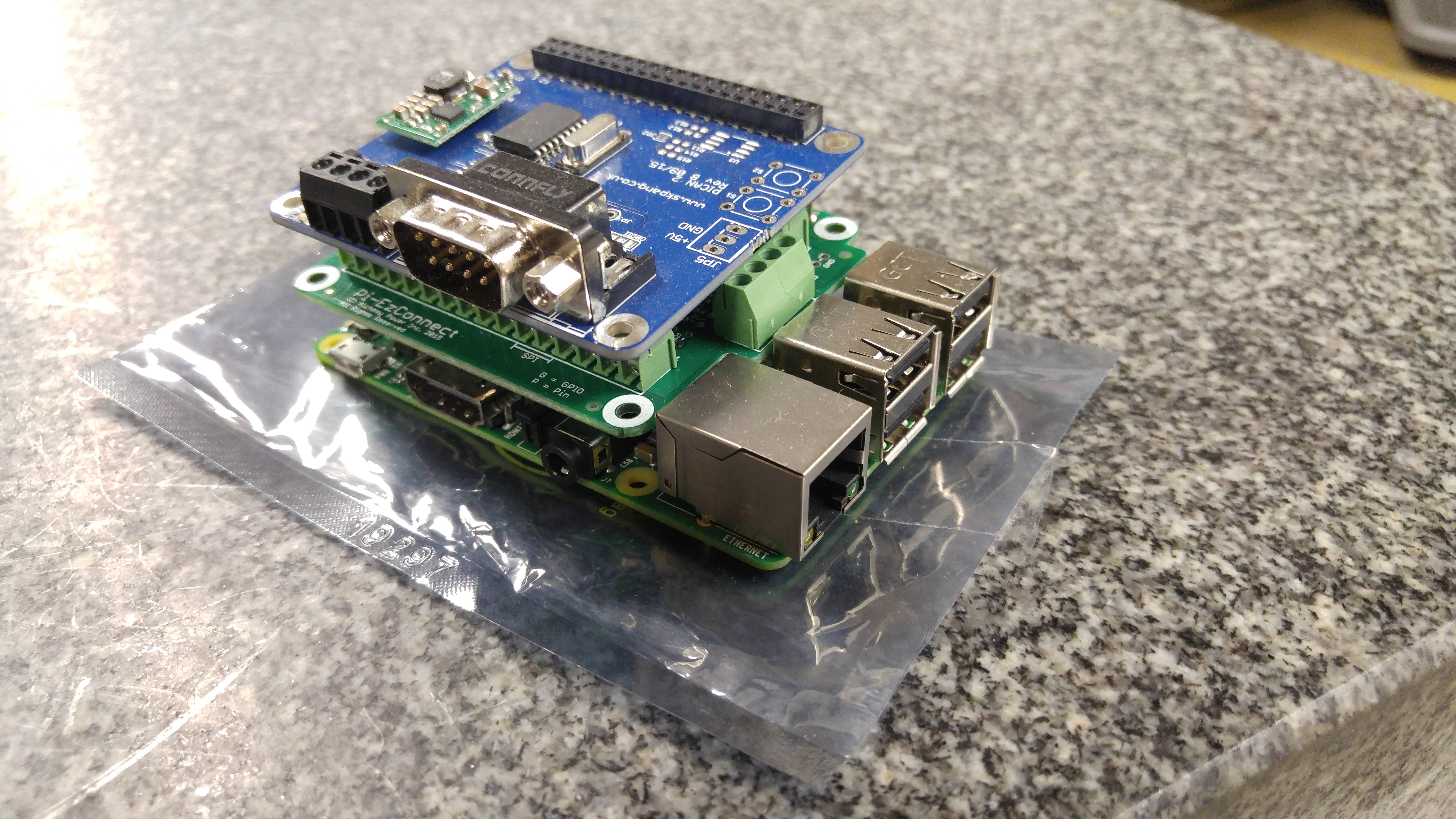

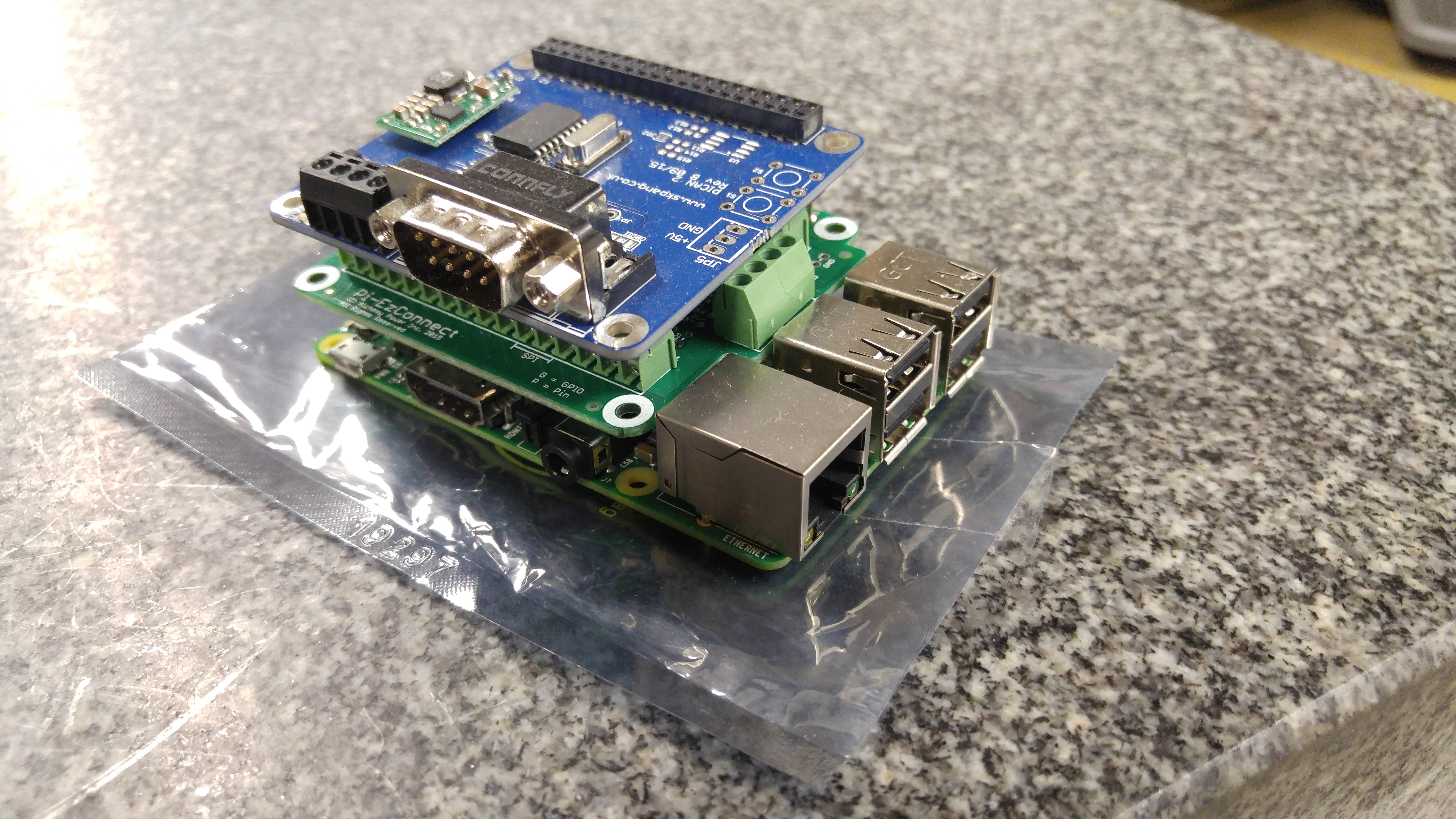

- Raspberry Pi Dashboard - 2016-2017

Developed full hardware and software stack to implement a Raspberry Pi as

the driver interface. The controller displayed onto a 5" TFT LCD, showing the

driver useful engine parameters and status bars, such as water temp, oil temp,

oil pressure, battery voltage, and gear position, with a tachometer across the

top.

- Utilized python for backend interaction with ECU via CAN bus.

- Frontend developed in Javascript for ease of quick revision.

- Handled the very time-sensitive operation of shifting control, issuing

commands to the power distribution unit and engine control unit to

orchestrate a perfect gear shift.

- Used systemd in Raspbian Lite OS to reduce amount of background processes

taking up excessive overhead.

- Was easily adapted for use on team's first Electric Car to monitor

accumulator state-of-charge, temperature, motor current, motor RPM, and

much more.

- Utilized built-in wi-fi to allow for wireless updates and debug.

The hardware stack for the dashboard.

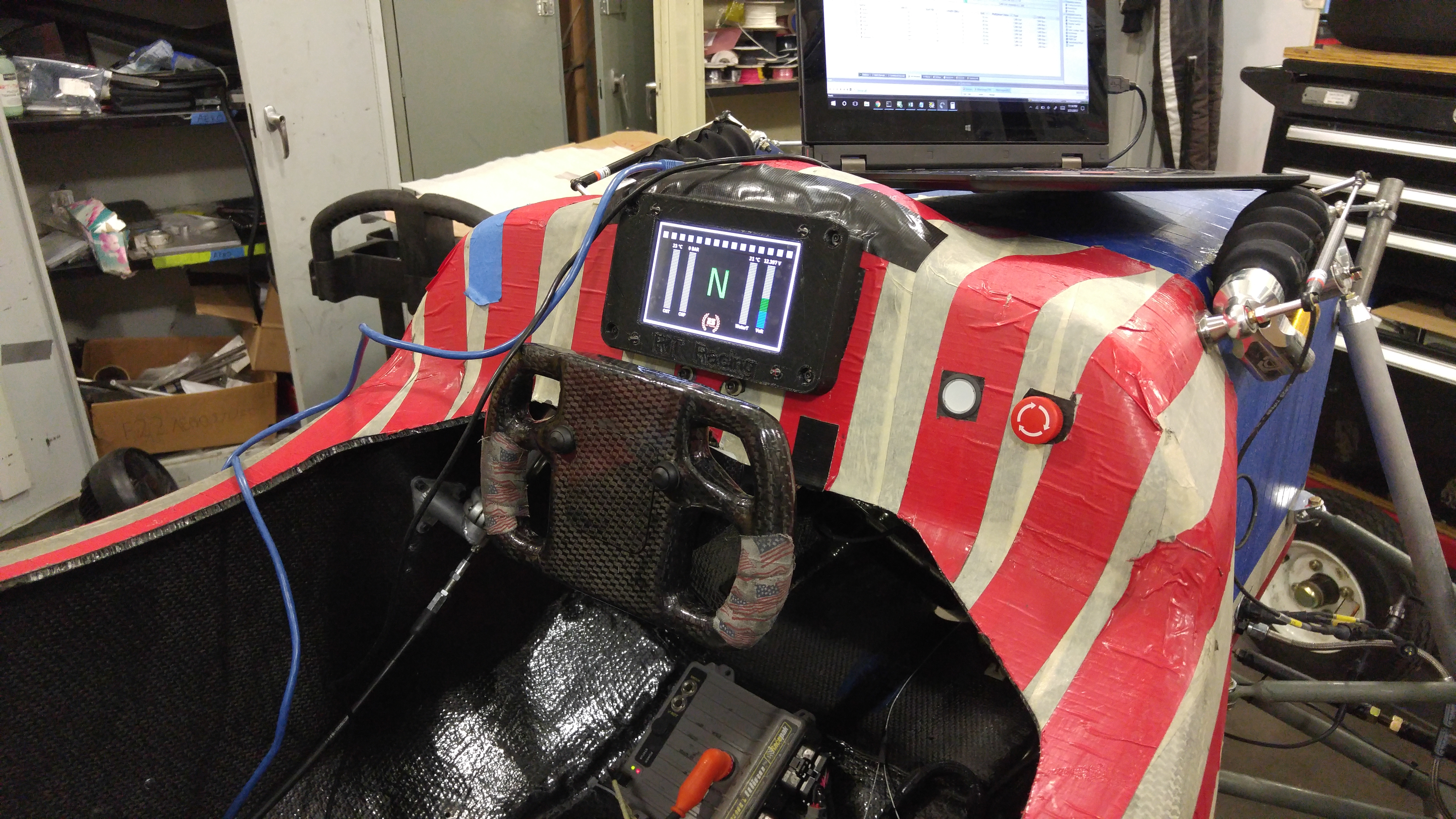

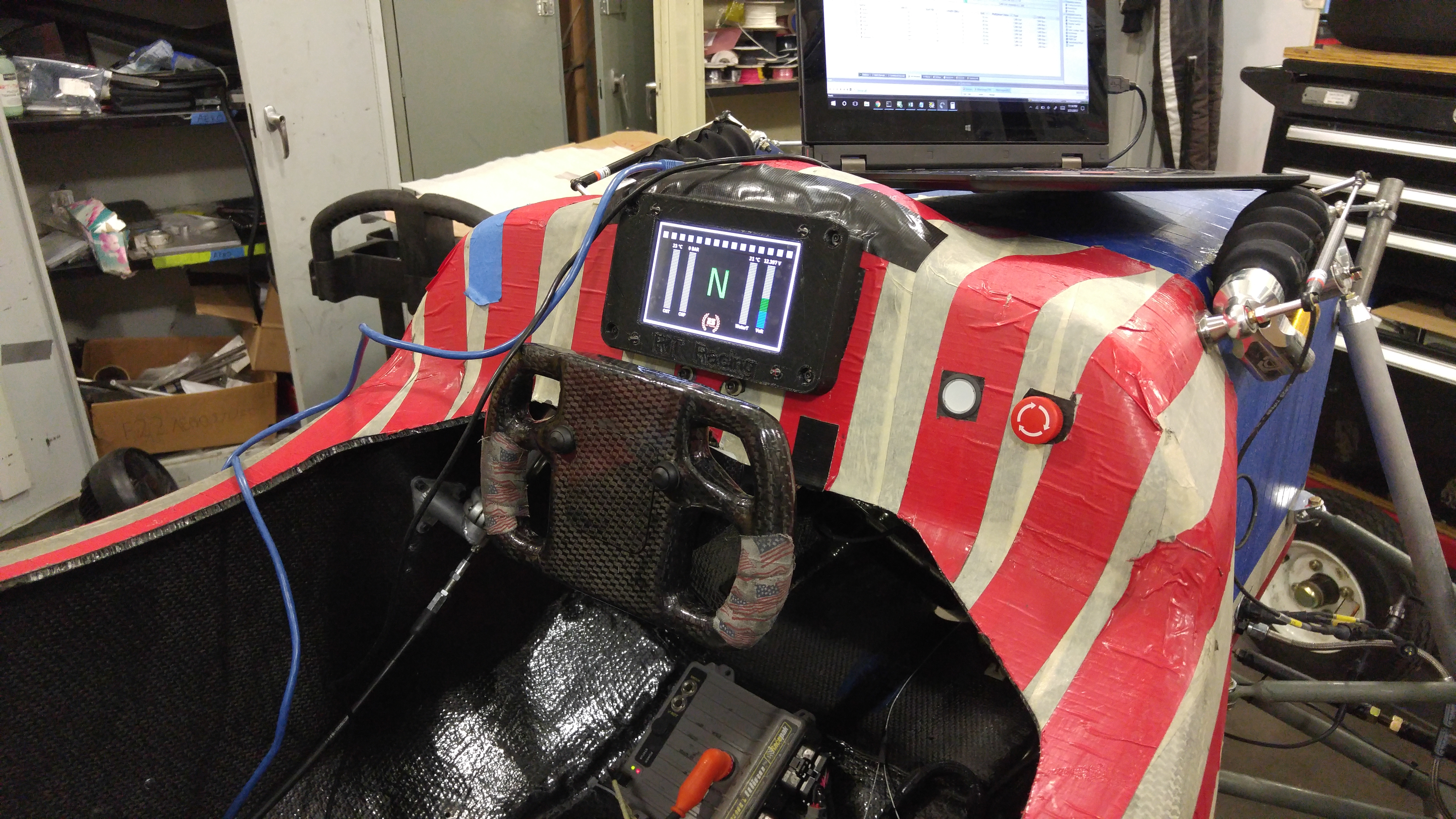

The display mounted on the 2017 car during prototyping.

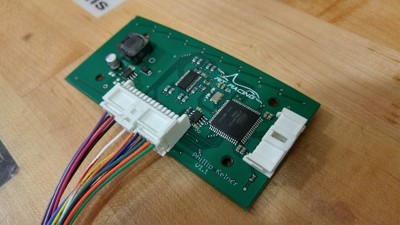

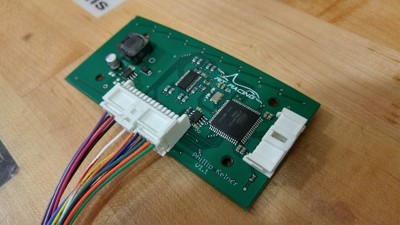

- Custom Embedded Dashboard - 2015-2016

First dashboard used an AT90CAN128 microcontroller on a custom PCB whose

schematic and layout were done in EagleCAD PCB Design Software. Board contained

many of the same features as the later Raspberry Pi dashboard, albeit with

severely limited abilities for flexibility. This board competed on the 2016 car.

- Contained 10 RGB LEDs for use as shift lights, and 4 more to indicate engine

status and/or warning lights.

- Received data from ECU via CAN. Exposed UART for debugging.

- Firmware written in C.

- The car's drivers reported being able to time perfect shifts using shift lights as guide.

The PCB for the original dashboard.

Designed and assembled wire harnesses that integrated power distribution and data

acquisition in an electrical system that at the time lacked integration.

- Introduced a Data Acquisition system as part of the car's permanent controller

network.

- Implemented wire strain relief and mechanical fasteners to improve harness

reliability and maintainence.

- Designed new wiring schematic from scratch using PTC Creo Schematics.

The primary controller branch for a car's wiring harness.